Manufacturing Capabilities

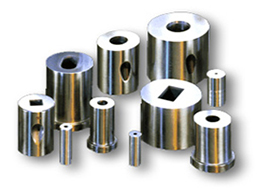

Custom Machining

Moeller’s machining capabilities are the most technologically advanced in the industry. Our extensive array of equipment capabilities includes CNC Conventional / Wire EDM, CNC Turning and Milling Machines, CNC Jig Grinding and Profile Grinding. Moeller’s climate controlled inspection department features CMM equipment, SPC quality control and certification capabilities.

3D Part Digitizing

Moeller Precision Tool’s ability to engineer and manufacture tooling for today’s demanding production environments extends far beyond traditional engineering and design practices.Our investment in the most current reverse engineering technology, including 3D laser scanning, allows us to precisely capture critical part data, and then manufacture exact replicas.

Engineering

Moeller’s experienced engineering staff provide unsurpassed quality and innovation for the special tooling required in the metal stamping, forming, piercing and trimming industries. Our quality practices apply to both standard and custom detail tooling, providing cost-effective manufacturing while providing world class performance from every part produced.

Facilities

Moeller Precision Tool

Corporate HQ

30893 Century Drive, Wixom, Michigan 48393

PH: 248.668.1166

FX: 248.668.1004

E-mail: quote@moellerpunch.com

Moeller Precision Tool South

3048 Owen Drive, Antioch, Tennessee 37013

PH: 615.371.0992

FX: 615.371.9190

E-mail:

quote@moellersouth.com

Moeller Precision Tool de Mexico

Circuito El Marques Sur # 43 Parque Industrial El Marques, Queretaro C.P. 76246

PH: 442.253.12.00

FX: 442.250.12.01

E-mail: cotiza@moellerdemexico.com

Moeller Precision Tool Canada

225 Boida Ave, Ayr, ON Canada N0B 1E0

PH: 519.623.1144

FX: 519.623.1004

E-mail: quote@moellercanada.com

Moeller Precision Tool Europe SRL

Via Don Minzoni 26

20056 Trezzo sull’adda (mi) Italy

PH: +39 (0)2 90937311

E-mail: quote@moellerpunch.eu

Dynamic Die Supply

3048 Owen Drive, Antioch, Tennessee 37013

PH: 615.490.6466

FX: 615.577.3704

E-mail: quote@dynamicdiesupply.com

https://dynamicdiesupply.com/

AW Precision LTD

Rugby, Warwickshire

CV21 1QN, United Kingdom

PH: +44 (0) 1788 542271

E-mail: sales@awprecision.co.uk

Moeller Precision Tool, founded in 1965, encompasses over 100,000 square feet of manufacturing and warehouse space.

MPTCrib.com, Moeller’s Inventory Management Software, was developed to maximize crib efficiency with automated tooling parts/component management. Adaptable to most manufacturing areas including existing storage methods and systems, our barcode parts scanning system catalogs components, provides inventory control, automatically uploads data, and warns before stock levels become critical.

Learn more about MPTCrib.com, our exclusive inventory management program here.

The latest version of M-CAD is online!

M-CAD is our web-based, on-demand 3D tooling catalog where you can find:

- Geometrically accurate product models of Moeller’s standard and custom tooling components

- User configured, native, solid models available in vast array of file formats

- Exclusive Moeller products like True Strip, True-Fit (and more)

- Smart Models including the part properties for seamless design and BoM integration